Recycling Pilot Project

Proving the feasibility of closed-loop recycling for post-consumer window glass

Every year, 500,000 tons of window glass are discarded in Switzerland, which is about 16 kg per second – the equivalent of a standard kitchen window. Yet for now, none of this glass is recycled to make new window glass. With this pilot project, we aim to prove that circular economy in the Swiss float glass industry is possible!

Every year, around 500,000 tons of window glass are discarded in Switzerland – about 16 kg per second, the equivalent of a standard kitchen window. Until recently, none of this glass was recycled into new flat glass: most ended up in landfills (82%) or was downcycled (18%) into container glass or insulation.

In the summer 2025, the pilot project Windows of Opportunities, led by ZHAW with the support of the Federal Office for the Environment (FOEN), Glas Trösch, SWICA, and the Birchmeier Group, demonstrated that local and circular flat glass recycling is not only possible but necessary.

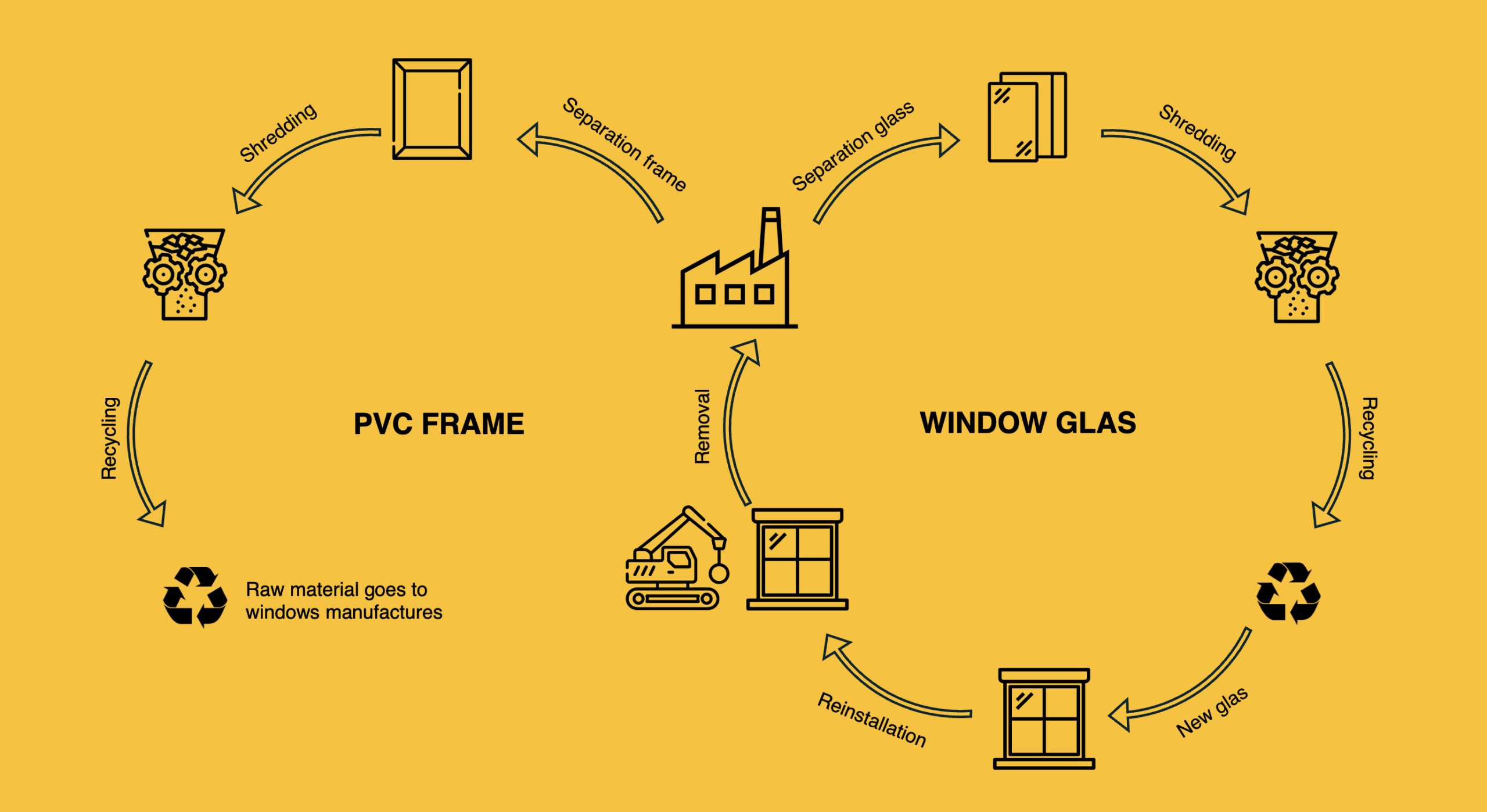

At a demolition site in Winterthur, 375 window sashes — representing 4.4 tons of insulating glass and 3.5 tons of PVC frames — were carefully dismantled, transported, and stored. The glass was then manually separated from the frames, which were recycled by Moser Recycling, before being sent to a specialized facility for cleaning and sorting. The purified glass fragments were finally delivered to a float glass factory, where they were successfully melted into new flat glass.

The pilot project focused on organizing and documenting every step of the process — from dismantling to remelting — in order to assess the technical, ecological, and logistical feasibility of flat glass recycling in Switzerland. Each stage was recorded and analyzed to identify challenges such as contamination, transport logistics, and material handling on site.

The results show that clean and careful dismantling is essential for successful recycling: the integrity of the glass plays a decisive role in whether it can return to float glass production. Collaboration between demolition experts, recyclers, and the glass industry proved key to achieving high-quality outcomes.

For the first time in Switzerland, the project was able to demonstrate that post-consumer insulating glass can be reintroduced into the float glass production process. This achievement confirms that, with the right methods and coordination, closed-loop recycling of window glass is technically possible within existing infrastructures.

Process

Recycling

This summer, ZHAW, together with Glas Trösch Group, SWICA, Birchmeier Gruppe and with the support of FOEN, launched a pilot project on flat glass recycling.

At the SWICA building in Winterthur, 375 window sashes were dismantled, stored and separated by material before demolition. The goal: to reintroduce recycled flat glass into the replacement building designed by Adrian Streich Architekten – creating a closed loop for windows.

Dismantling

Normally, dismantled windows are thrown into containers together with other materials. At the recycling yard, only about 18% of flat glass is downcycled as container glass, while the majority still ends up in waste incineration plants.

In the pilot project, however, the window sashes were carefully dismantled using simple tools – an essential step towards reuse and proper recycling.

Storage

Dismantling sashes is only the first step. To meet strict flat glass recycling standards, storage and transport also matter.

In Winterthur, sashes were lowered by excavator instead of being carried down stairs, and stored vertically in flat containers. A key requirement: the glass had to remain intact to avoid cross-contamination with other materials.

Separation

As part of the flat glass recycling pilot project, the separation of insulating glass units from their frames was successfully carried out. The conditions proved to be particularly favorable: the glazing was not clued at any point, allowing for a quick and uncomplicated removal process. The window sashes were positioned vertically on stands, the glazing beads were removed, and the insulating glass units could then be cleanly extracted and placed in the designated container for clear glass.

Cullets

The collected insulating glass units were processed into cullet and reintroduced into float glass production! After thorough sorting and treatment, the glass from insulating units could be directly reused in the manufacturing of new flat glass, confirming the technical feasibility of post-consumer glass recycling in Switzerland.

This achievement marks a major step forward towards a true circular economy for window glass.

And the frames?

As part of the pilot project, the PVC frames were also recycled. After dismantling, they were cut, processed, and turned into recycled PVC granulate, reintroduced into the production of new window profiles.

Today, PVC recycling represents the most advanced circular system in the window industry, enabling a closed material loop.